“3 Ways to Manage COVID-19 Disruption on Your Supply Chain” Was published by SourceDay CMO Sarah Moore on March 16, 2020. you can read the full article HERE.

“How many of your PO lines have exceptions?” – Account Executive at SourceDay

“These days? All of them.” – Global CPG Manufacturer

Manufacturing is no stranger to change, but the coronavirus is changing the game. Schools are closing, and companies have told employees to work from home. Major sporting events and tradeshows are canceled or postponed. Supply chains have started to experience all kinds of disruption. Some will struggle to keep up with record demand, as consumer fears create runs on toilet paper and canned goods. Others will shut down production because of canceled orders and watch their inventory pile up.

Unfortunately, most manufacturers depend on email and spreadsheets to manage open orders with their suppliers. Rather than foster resilience, this approach makes it more likely that they will struggle to manage the impact this global pandemic could have on their businesses.

As the supply chain point person, I rest easier knowing that SourceDay can bring me completely up to date in short order!

Troy Mauk

Director of Global Procurement at Global Interconnect

In the year 2020, there’s no need to depend on manual updates to spreadsheets and ERP systems. By using SourceDay’s cloud software and managed services, you can have a single source of truth on every line of every order. And it can be accessed by your teams from anywhere at any time.

“I immediately started looking at SourceDay to see what was confirmed and what was late. I put priorities on the hotlist, and said to our suppliers, ‘here’s what you need to focus on for the next 4 weeks.’ We implemented critical use of the ‘Hot List’ function to shepherd our suppliers in deliveries and to gain real-time insights into confirmed shipments.”

Troy Mauk

Director of Global Procurement at Global Interconnect

3 Ways to Manage COVID-19 Impact

There are three primary ways SourDay solutions help you manage the unprecedented impact COVID-19 could have on your supply chain:

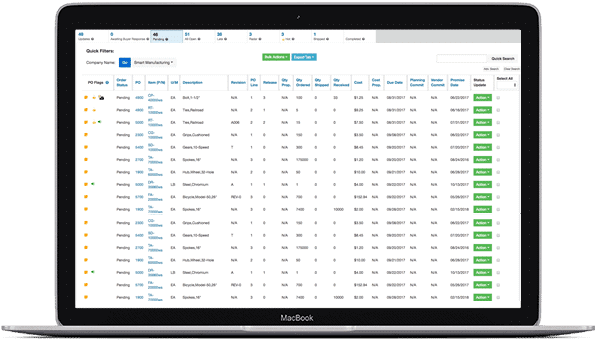

- Get real-time visibility to all open orders. Use SourceDay to move your open order report online so buyers and suppliers can collaborate on changes to dates, quantities, and pricing. Any approved change is automatically updated in your ERP. This will give your demand planning engine accurate supplier order fulfillment data and lets the whole business know what to expect on every line of every order.

- Help your buyers and suppliers focus on the most critical exceptions. SourceDay automatically filters POs to help buyers prioritize the most important exceptions that might impact production. When buyers and suppliers spend less time updating each other in email, spreadsheets, and data entry, they spend more time making sure you ship your orders on time.

- Contain cost with streamlined communication. As customer demand shifts throughout this crisis, Sourceday can help you stay on top of changes that could drive up costs. Communicate push-outs and pull-ins more quickly and systematically. Use SourceDay software to safeguard against price gouging and excess inventory.

As SourceDay CEO Tom Kieley wrote last week, the manufacturing industry is resilient. It’s weathered countless global crises because its leading companies found innovative ways to overcome unprecedented challenges. We’re being called to do that again now.

Use SourceDay Free for 90 Days

COVID-19 has moved our supply chains into uncharted territory. Global and local leaders worldwide are ready to do whatever it takes to ensure they continue to run as smoothly as possible. SourceDay’s mission has always been to do the same. That’s why we’ve decided to offer new customers the SourceDay PO Collaboration and RFQ Collaboration solution free for the first 90 days. We know this global pandemic will make the next few months particularly challenging. But we also know we can help you get through this stage if we start now.

Together, we’ll get through these unprecedented times.

- Sarah Moore, CMO at SourceDay

About SourceDay

SourceDay’s platform provides a digital interface between a manufacturer’s ERP system and hundreds of suppliers, automatically updating changes to delivery dates, pricing, and quantities throughout the order lifecycle and across the supply chain. Replacing manual processes with software improves customers’ understanding of the many changes that occur throughout the lifecycle of an order. Procurement teams stop spending their time on fire drills and reacting to expensive surprises. Now they have time to manage suppliers more strategically, proactively addressing pricing and quality issues and ensuring their factories receive the materials they need to meet customer commitments on time.

About Encompass Solutions

Encompass Solutions is a business and software consulting firm that specializes in ERP systems, EDI, and Managed Services support for Manufacturers and Distributors. Serving small and medium-sized businesses since 2001, Encompass has helped modernize operations and automate processes for hundreds of customers across the globe. Whether undertaking full-scale implementation, integration, and renovation of existing systems, Encompass provides a specialized approach to every client’s needs. By identifying customer requirements and addressing them with the right solutions, we ensure our clients are equipped to match the pace of the Industry.