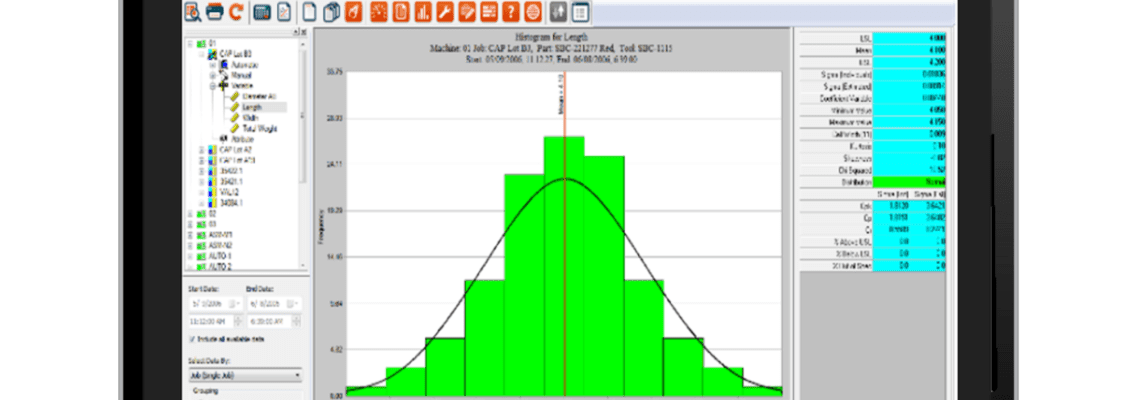

Improve your quality management program with timely feedback and pre-emptive responses with the Epicor Advanced MES Statistical Process Control and Statistical Quality Control module.

What is Statistical Process Control (SPC)?

Statistical Process Control will allow you to analyze the processes from your machines using various statistical techniques. Using the data that is being automatically collected, you will be able to make adjustments to the process to help ensure the process is statistically in control and to improve the machine process capability. Without SPC your technicians can only respond to nonvisual issues when they are measured by your quality team. By the time the issue is discovered the process is already producing defective parts. Using SPC, technicians can be alerted to a process that is violating spec limits thus minimizing the production of defective parts.

What is Statistical Quality Control (SQC)?

Statistical Quality Control will allow you to analyze the variable data as well as the attribute data of the part. Using an advanced manufacturing execution system, your operators and quality technicians can use a Human Machine Interface to enter or pull in quality measurements. Using the data, you will be able to determine if the measured part dimensions are statistically in control.

Advanced MES Statistical Process Control and Statistical Quality Control

Statistical Process Control (SPC) and Statistical Quality Control (SQC) with Epicor Advanced MES use real-time, automatic data to help you respond to production conditions before making bad parts. SPC and SQC with factual data enable consistent results without constant oversight. They compare cycle time and process data to control the limits you set—providing rich, instant information to machine operators, quality and reliability engineers, and maintenance professionals.

Advanced MES SPC and SQC Features

Improve Your Quality Management Program with Advanced MES and respond to conditions before producing bad parts, thanks to:

- Advanced MES operator interface embedded in the system

- Easy operator interface for setup, alarming, and correction

- Sophisticated modeling tools

Additional benefits include the ability to:

- Conform to Quality Standards

- Avoid charge-backs and defect penalties

- Automatically scrap parts

- Drive continuous improvement into your quality programs

Any machine that feeds production and process data into your Advanced MES system can benefit from the Advanced MES SPC and SQC capabilities. It’s capable of receiving any kind of data from machines—cycle time, temperature, pressure, weight, dimensions, or any other kind of measurement. Set and record process parameter control limits for each attribute, and specify sampling criteria. The system automatically administers data samples and alerts for out-of-spec conditions. It applies statistical analysis to process conditions, so operators get an alert—even before things run out of spec—that something is trending negatively.

Process Sheets

Within Epicor Advanced MES you can set up process sheets for the machine/part/tool combination that you wish to monitor. Within the process sheet, you can set up control limits for the process parameters being monitored. The process sheet allows you to configure the frequency and subgroup size for your sampling and you can set up alarms for how you wish to handle process violations.

Edge Computing and Automatic Part Qualification

Automatic part qualification can be set up based on your process sheet parameters to help determine what to do when a part violates your rules. Using our edge device – the Connect Factory Machine Interface Unit (CF-MIU) you can control what you want to have to happen when a process rule is violated.

The Mattec Machine Interface Unit (MIU) is an industrial strength data collection device conceived, developed, and manufactured by Epicor, and was designed along the lines of a SCADA (Supervisory Control and Data Acquisition) system. The term SCADA generally refers to a system that monitors machines, groups of machines, or large cells of manufacturing equipment. Much of the control is performed automatically by the MIU, however, there are host control functions that permit overriding this autonomous control through supervisory actions or intervention. For example, the MIU can control the output reject chute based on various conditions and processes. The MIU is ensuring that every part is manufactured according to engineering specs provided at the host. Its main purpose is to collect production and process information from the manufacturing machine, store, and transmit that data in real-time to the server computer.

The MIU can interface with non-OPC PLCs on the factory floor as well as read its own internal set of analog and digital inputs. The data acquisition begins here through meter readings, level indicators, pressure and temperature status readings, etc., which are then forwarded to the SCADA engine on the MIU. Data is then compiled, and formatted, various reduction analysis equations are executed, and outputs are engaged if needed. In real-time, the operator can make supervisory decisions to adjust or override normal processes and procedural functions.

Advantages of SPC and SQC together

By bringing the SPC and SQC data together, you can analyze the association of the different processes to the dimensions of the part. This gives your process techs additional insight into troubleshooting process issues, and will also assist you in determining which processes are critical and guide you on setting the specifications and control limits.

Do More for Quality Management Than Gather Data

With Advanced MES, statistical analysis is easy and accessible because it’s automated and visual. Epicor eliminates the need for a statistician—or even advanced mathematics training—to put SPC and SQC to work for your company. SPC and SQC do all of the work in the background and serve up visually intuitive graphs and charts that are designed for fast, easy understanding by operators and engineers alike. Complete, accurate, and automated data collection—combined with powerful analysis in a meaningful format – empower people at every level to use statistical analysis to plan, respond, or react to help ensure quality. The Advanced MES SPC/SQC module supports:

- Automatic process samples

- Intermittent or batch checkpoints

- Continuous background analysis and computations

- Process exception alarms

- Real-time quality displays for operators and managers

- Linear regression analysis

- Exception logs and reports

- Control of limit calculation

- Statistical analysis historian

- Any kind of MRO activity like cleaning, changing parts, taking measurements, making adjustments, performing inspections, and others

- Adjustment of production schedule automatically for PM/MRO

- Machines, tools, auxiliary equipment, and another type of assets

- Tasks, schedules, and requirements from ERP, MRP, and maintenance systems

About Encompass Solutions

Encompass Solutions is a business and software consulting firm that specializes in ERP systems, EDI, and Managed Services support for Manufacturers. Serving small and medium-sized businesses since 2001, Encompass modernizes operations and automates processes for hundreds of customers across the globe. Whether undertaking full-scale implementation, integration, or renovation of existing systems, Encompass provides a specialized approach to every client’s needs. By identifying customer requirements and addressing them with the right solutions, we ensure our clients are equipped to match the pace of the Industry.