Top 10 Benefits Of IoT For Manufacturers

Chances are you have come across the terms Internet of Things (IoT) or the Industrial Internet of Things (IIoT). These are networks of connected devices that communicate data to a central system to make sense of it all. These networks consist of connected edge devices, terminals, and machines in an enterprise. The data captured through this network provides an understanding of what is successful and what is not in terms of operations and processes. The system that helps you interpret the captured data is, more often than not, your company’s ERP system. Read on to learn how you can leverage the top 10 benefits of IoT for manufacturers in your facility.

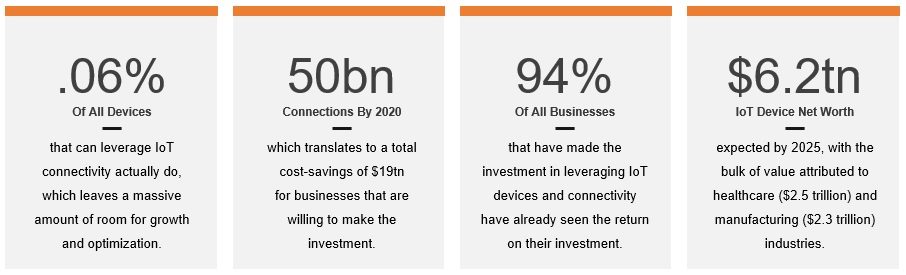

Internet of Things (IoT)

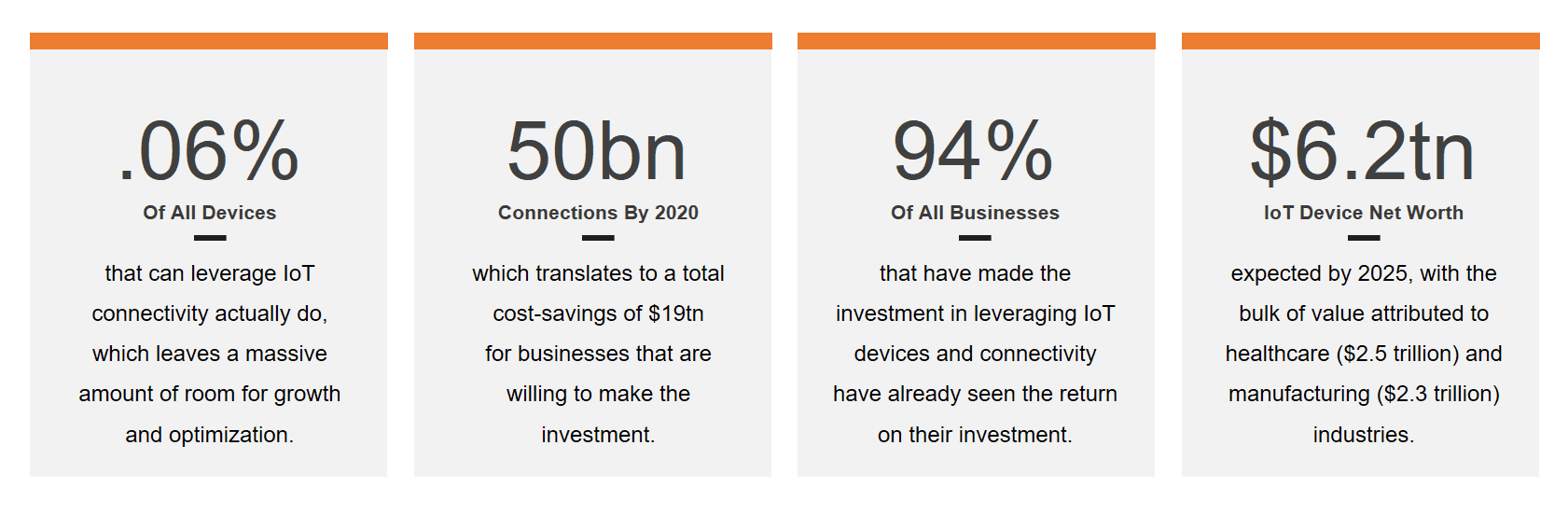

When it comes to everyday devices capable of the connectivity we are talking about, the numbers are staggering. Billions of devices exist with this capability. It is estimated that there are roughly 7 such devices for each person on the planet, totaling roughly 50bn devices by 2020.

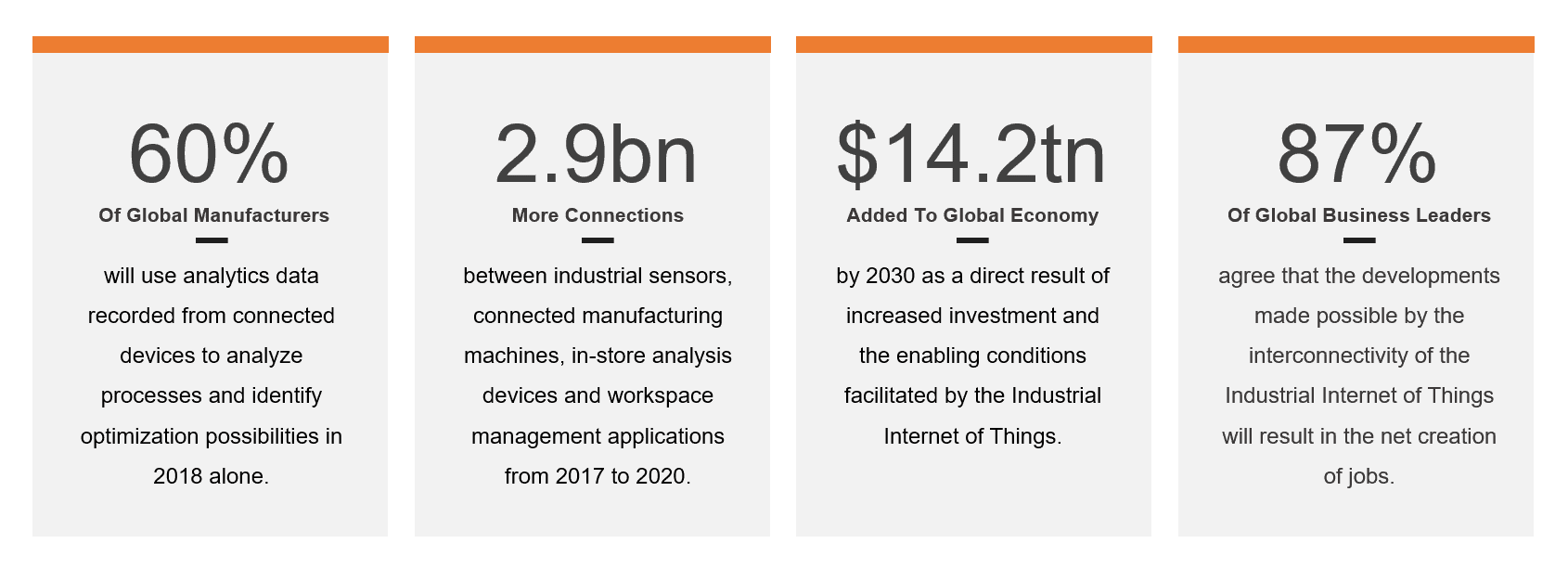

Source: CSGI, Intel, Vision Critical, pfsk

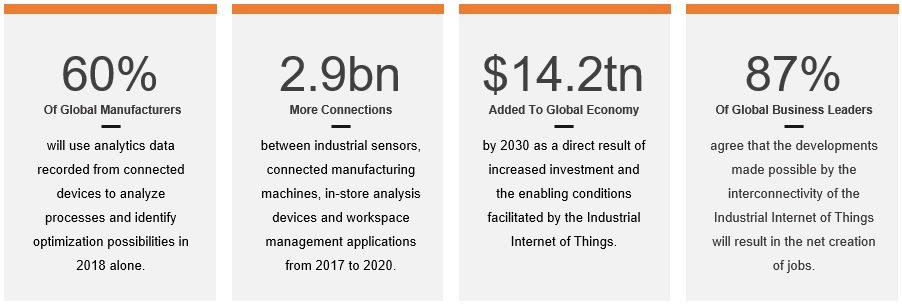

Industrial Internet of Things (IIoT)

When it comes to IIoT devices, the vast majority reside in manufacturing, followed closely by the healthcare and retail industries. The Industrial Internet of Things (IIoT) puts a focus on this interconnectivity and data provided by the terminals, sensors, and other systems on the factory floor. These data-fueled factories become “intelligent” environments, which are capable of informing enterprises from the top down. They provide visibility regarding the efficiency of factory processes and performance both in real-time and over time. In short, the data enables manufacturers to refine and improve operations with relevant and up-to-date data.

Source: Accenture

So, how can your organization stand to benefit from investing in IoT connectivity? Here are the top 10 benefits of IoT for manufacturers.

1. The Connected Factory – Blindspots Begone

IoT-enabled machines and endpoints are capable of communicating operational information to personnel both inside and peripherals to your organization. That includes machine operators, managers, field service personnel, and even partners like suppliers, subcontractors, and OEMs. This connectivity delivers mission-critical data and information to operation managers and factory leadership on-site and out-of-office. The power to control operations and manage factory activity on a remote level increases opportunities for process optimization and automation. view the Connected Factory In Action infographic at Manufacturing Tomorrow.

2. Production Visibility – Identifying Bottlenecks And Improve Processes

When it comes to production, the continuous monitoring of processes that IoT connectivity provides will enable improvements to be made on a rolling basis. Hangtime in assembly and manufacturing operations gain particular benefit when bottlenecks are identified and adjustments can be made in nearly real-time to realize better approaches to production management and the reduction of operational costs. Additionally, part waste is reduced alongside fewer resources tied up in inventory and better overall product delivery. For some organizations, IoT connectivity will lead to a 15 percent productivity increase in delivery and supply chain performance.

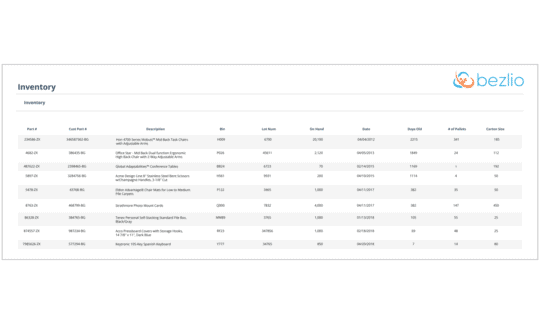

3. Better Inventory Management – Find It Fast, From Anywhere

With technologies like RFID and IoT connectivity, personnel tasked with managing inventory can leverage automated asset tracking and reporting through ERP to avoid the costly mistakes that come with working within antiquated inventory tracking systems. This connectivity allows items to be tracked and the data recorded to the ERP system automatically. These performance management capabilities made possible through IoT connectivity and ERP can help organizations reduce the number of working hours committed to inventory management each month and reduce the probability of human error. Track your stock from shop to dock with IoT technologies in your facility.

4. Build A Safer Work Environment

While there are no doubts that IoT connectivity and ERP improve production on the factory floor; these technologies can also help create a safer working environment for employees. This can be in the form of vision and spatial awareness systems for human-machine interactions or wearable safety technologies your staff keep on their person throughout the day. There are several safety concerns in any manufacturing facility. IoT-connected devices can communicate to larger systems within the organization of aberrations, such as too much vibration or heat being exhibited from a machine or pressure loss within piping segments, and even gas leaks that might be otherwise undetectable to human perception. Staff moving through dangerous parts of your facility can signal to connected machines that a human is nearby and appropriate action can be taken automatically. An employee that sustains an injury in a remote location of the facility or even off-site can receive faster care with the inclusion of IoT-connected safety equipment. These are only a handful of examples of how IoT for manufacturers can improve safety in your facility.

5. Secure Your Facilities

With a growing number of bad actors participating in malicious attacks on manufacturers across the globe, manufacturing facility security is a topic of conversation every organization should be discussing. When it comes to security, IoT provides manufacturers with a way to monitor their data coming into the system as well as going out. Terminals and end-points can signal foreign devices being connected to infrastructure, large amounts of data being moved, and individuals accessing data they otherwise shouldn’t have access to. Leveraging IoT for manufacturers can help guard against security threats to vital hardware, software, and cloud-stored data. You can even manage devices and policies throughout an enterprise from a single point using IoT connectivity. For more information on Practical Security for the Internet of things – view the infographic from Entrust.

6. Predictive Maintenance – Minimize Machine Downtime

Predictive maintenance identifies the condition of equipment while it is in service and determines the optimal service interval. It saves time and money by completing maintenance activities only when necessary. A special focus has been placed on predictive maintenance, as opposed to preventative maintenance, more recently. This is because it allows longer periods of operation between maintenance tasks, resulting in less downtime for essential machinery. When coupled with technologies like IoT for Manufacturers, everything from vibration, voltage, temperature and other performance indicators feed into sensing tools attached to machines. This information is interpreted and visualized by intelligent software solutions, such as ERP platforms, into updates, warnings, and alerts. Your teams can use this information to evaluate the situation and take the most appropriate action. Intelligent and connected devices assist in setting data points that indicate when a part is reaching end-of-life, too. Automated systems can be directed to order replacement parts if none are on-site and schedule the replacement or repair in such a way that minimizes unplanned production downtime, which can cost manufacturers as much as $300,000 an hour.

The Volvo Group provides one real-world example of how an IoT-based predictive maintenance solution can predict damage to spindles, as well as identifies cracking and spalling of rotating equipment, gearing, and motor defects. The resulting improvements to OEE saw a 70 percent reduction in diagnostic time and a 25 percent reduction in repair times.

7. Predictive Forecasting – Real-Time vs. Historical Data

Today’s global economies move too quickly for manufacturers to rely on historical data to forecast demand. Weather events, materials shortages, and a host of other environmental factors can influence demand for any given product at any given time. Accurate forecasting is critical for manufacturers that want to sell as much of a product as possible without oversaturating their markets.

Take, for instance, a widget. A consumer buys a connected widget, which in turn collects data about usage, wear and tear, and overall performance. The relative data is then sent back to the manufacturer to determine what adjustments need to be made to the product for more predictable forecasts of future demand. If the product is satisfactory for customers across a wide range of environments and uses, then the average life-cycle can be taken into account, and manufacturing volume can be adjusted to match. The result is more accurate demand forecasting, fewer wasted resources, and stock tied up in inventory. What follows is an increase in overall customer satisfaction based on quality and deliverability when consumers return for a replacement part.

IoT for Manufacturers in this sense can go far beyond demand forecasting to include the entire supply chain with traditional forecasting, statistical bottom-up forecasting, and ship-to forecasting. Zara is one retailer using IoT to forecast demand and minimize waste.

8. Increased Energy Efficiency – A Smaller Footprint

If you didn’t already know, industries like discrete and process manufacturers are responsible for the majority of energy consumption worldwide. Industrial manufacturing is responsible for consuming 54% of globally delivered electricity. This leads to pretty sizable operating costs. fortunately, IoT for manufacturers can significantly increase energy efficiency in several ways.

initially, managers can easily identify hardware and devices that use the most energy. This information can be used in creating advanced operating profiles that tell machines when to power up and operate or power down and conserve energy. Systems draining too much power, or more than they should be, can be a sign of malfunction. IoT connectivity can highlight these abnormalities right away and address problems more immediately than if the power consumption of machinery were not being monitored. This capability keeps machines operating at peak efficiency and capacity without draining resources unnecessarily.

Beyond this, IoT connectivity can give you an energy profile of your entire facility, or many facilities. The data can then be used to create the most appropriate and efficient backup systems to keep operations running smoothly despite adverse environmental factors. As a result, you can keep operating during tight deadlines and production schedules despite outages.

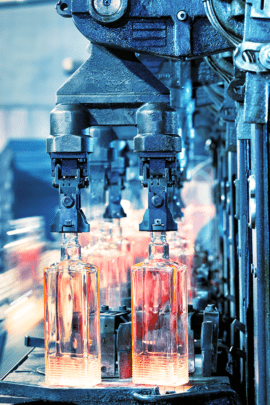

9. Improved Quality – IoT For Manufacturers’ Process Improvement

Quality can mean many things for manufacturers and their partners. Internally, improving processes through IoT devices can come from something as commonplace as alerting operators when there is too much material buildup on a machine’s end effectors or internal mechanisms. The addressing action would lead to improved machine performance, better output, and an improved process. in a temperature-controlled facility, aberrant tempt reading could be the result of a door left open, poor insulation, or a faulty HVAC system component. All of which can be identified and addressed with the help of IoT connectivity.

Alternatively, connected products and goods used in the field can relay valuable data that might not have been previously tested. This can include machinery performance when used in a cold, dry climate versus the humid tropics. Even phones that fail in freezing or sweltering temperatures can tell designers and engineers what components are of substandard quality, leading to improvements in future products manufactured with those conditions taken into account.

10. Increase Operational Efficiency – Maneuver Like A Tesla, Not An Oil Tanker

IoT-connected devices allow manufacturing operations and executives to utilize data flowing through their facilities to make smarter, more informed decisions. Using the information available enables the connected enterprise to undertake proactive, continuous improvement initiatives that create a more agile and stable future through both insight and action.

Truly, the benefits delivered by IoT-connected assets go beyond operational efficiency. The connected enterprise represents the next level of organizational maturity. It encapsulates predictive maintenance, higher quality products, more focused leadership, and overall organizational health. Overall, IoT for manufacturers allows staff throughout a company to work smarter, not harder, today. over the long term, cost benefits are realized many times over as upsets and disruptions in operations can be avoided entirely.

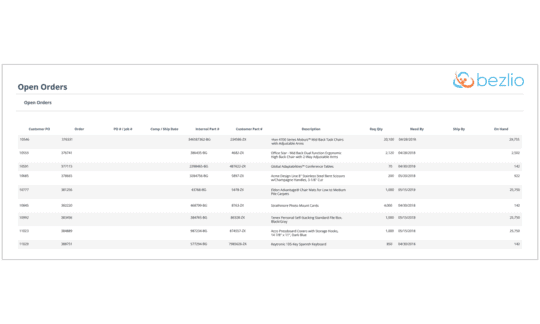

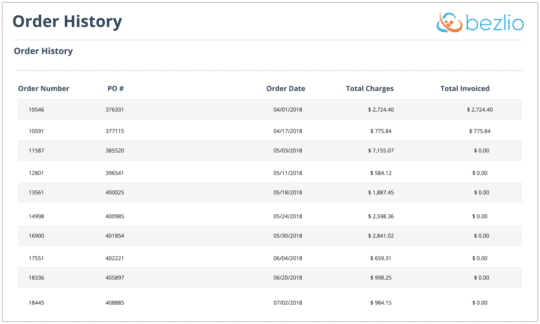

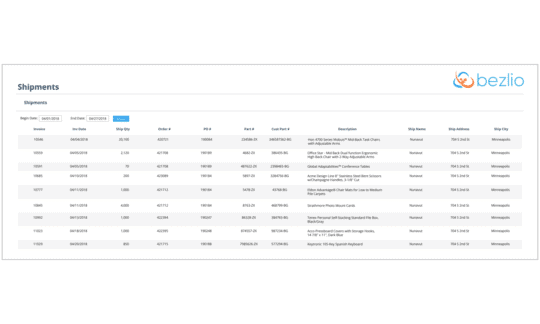

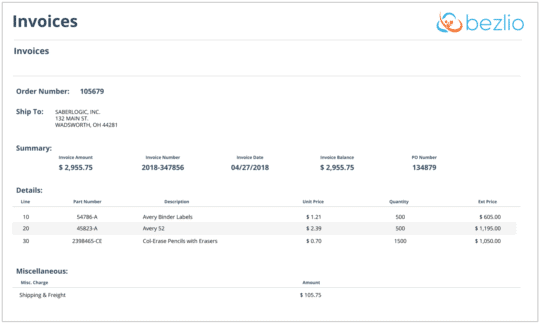

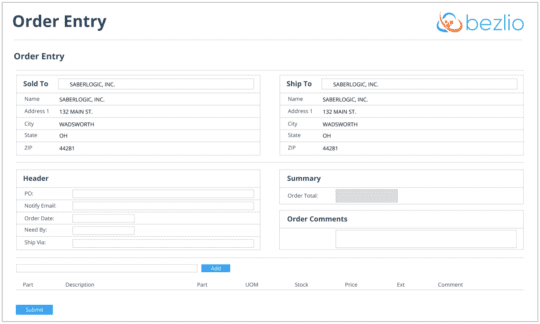

Epicor ERP IoT For Manufacturers – Workflow

Monitor equipment, assets, environmental factors, inventory locations, and their corresponding IoT data. Events and data—such as sensor and machine telemetry—flow into the Azure IoT Hub. From there, the data propagates to the IoT module of your Epicor ERP solution. Epicor IoT has an advanced rule-based engine that can detect patterns and raise alerts and notifications that propagate into Epicor ERP where they can be used to trigger business process changes like raising a maintenance suggestion when equipment degradation is detected.

Here are just some of the benefits realized when you implement Epicor ERP IoT for manufacturers:

- Identify issues such as potential breakdowns before they happen

- Optimize supply and reduce costs by monitoring events across your supply chain

- Improve overall workers’ safety and security in the plant by monitoring the KPIs of health and safety

- Improve decision-making by providing real-time, actionable information

- Increase customer satisfaction and efficiencies and lower costs

- Gain insights into the usage patterns and handling of products from customers

- Predict issues and reduce inventory by tracking materials, equipment, and product as it moves through the supply chain

Contact Encompass Solutions, Inc. to learn more about implementing Epicor ERP IoT for manufacturers using the link below.

About Encompass Solutions

Encompass Solutions, Inc. is an ERP consulting firm, NetSuite Solution Provider, and Epicor Platinum Partner that offers professional services in business consulting, project management, and software implementation. Whether undertaking full-scale implementation, integration, and renovation of existing systems or addressing emerging challenges in corporate and operational growth, Encompass provides a specialized approach to every client’s needs. As experts in identifying customer requirements and addressing them with the right solutions, we ensure our clients are equipped to match the pace of the Industry.